Welcome to the official website of Hubei ZhengJiu New Materials Technology Co., Ltd.!

Research paper by Professor Liu Hongzhi's research group at Shandong University: Rational design and preparation of cyclotetrasiloxane-based hybrid superhydrophobic cotton fabrics for oil-water separation and self-cleaning

2025-07-04

Research paper by Professor Liu Hongzhi's research group at Shandong University: Reasonable design and preparation of cyclotetrasiloxane-based hybrid superhydrophobic cotton fabrics for oil-water separation and self-cleaning

Innovation Points of the Article

This article introduces a novel superhydrophobic cotton fabric applicable to oil-water separation and self-cleaning. Using tetramethyltetravinylcyclotetrasiloxane as the starting material, a hydrophobic modification is carried out using a rapid and mild thiol-ene click reaction to prepare a cyclotetrasiloxane-based hydrophobic modifier. - Subsequently, sol-gel technology is used to introduce it into the cotton fabric to obtain a superhydrophobic cotton fabric. - The introduction of methoxysilyl groups can undergo dehydration condensation reactions with hydroxyl groups on the surface of the cotton fabric during the curing stage, allowing the coating to form in situ on the surface of the cotton fabric in the form of covalent bonds, thereby effectively improving the durability of the coating. Therefore, this superhydrophobic cotton fabric exhibits good stability, not only effectively resisting peeling and ultrasound, but also remaining stable under chemical damage caused by organic solvents, acids, alkalis, and salt solutions. The modified cotton fabric can effectively separate a series of oil-water mixtures with a separation efficiency as high as / 99.99% 99.99% This superhydrophobic cotton fabric has broad application prospects in oil-water separation and self-cleaning, and the cyclotetrasiloxane-based surface modifier can also serve as a strategy for modifying the substrate to achieve multifunctional applications.

Article Background

Superhydrophobic materials are a hot research area in materials science, combining practical value and innovative potential. In the petrochemical industry, leakage accidents occur frequently, and the metallurgical and leather industries also produce a large amount of oily wastewater, seriously threatening the economy, ecology, and human health. Traditional oil-water separation methods have limitations such as complex processes and low efficiency, while superhydrophobic materials, based on their unique wettability, not only exhibit excellent performance in antibacterial, self-cleaning, and anti-corrosion fields, but also show great potential in oil-water separation, which is of great significance for the development of new and efficient separation materials. /水分离方法存在工艺复杂、效率低等局限,而超疏水材料基于其独特的润湿性,不仅在抗菌、自清洁和防腐蚀等领域表现优异,更在油/水分离方面展现出巨大潜力,对开发新型高效分离材料意义重大。

Article Overview

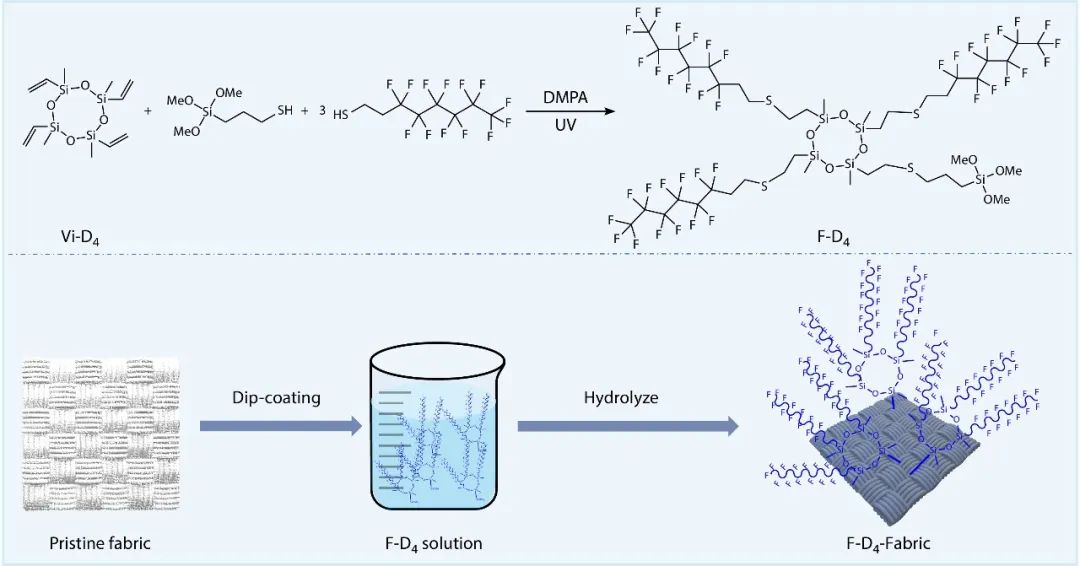

Based on the above background, Professor Liu Hongzhi of the School of Chemistry and Chemical Engineering, Shandong University research group introduced fluorinated substances and methoxysilyl groups into tetramethyltetravinylcyclotetrasiloxane via a thiol-ene click reaction under ultraviolet irradiation to synthesize a novel hydrophobic modifier -烯点击反应向四甲基四乙烯基环四硅氧烷中引入含氟物质和甲氧基硅基,合成了一种新型疏水改性剂 (F-D 4)。随后利用溶胶- Then, sol-gel technology was used to modify the original cotton fabric hydrophobically, thereby obtaining a superhydrophobic cotton fabric (F-D 4 -Fabric) Figure 1) 。

Figure 1 F-D4 preparation process and F-D4-Fabric preparation schematic diagram

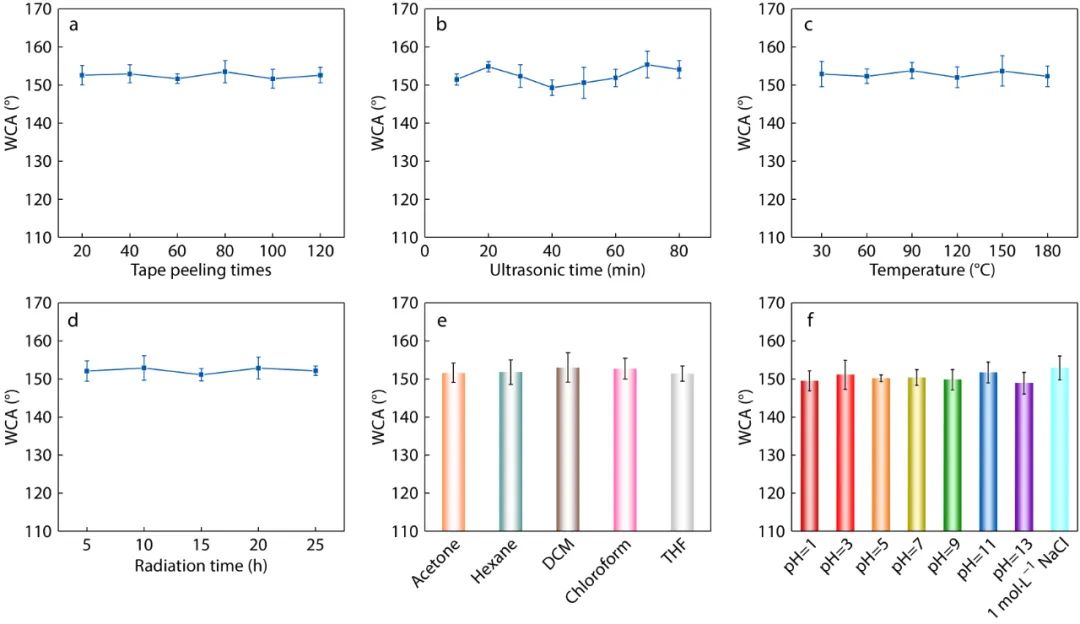

The article studies the mechanical, physical, and chemical stability of the modified cotton fabric ( Figure 2) Mechanical stability was evaluated by ultrasonic testing and tape peeling experiments. The results show that after multiple tape peelings and 80 minutes of ultrasonic treatment, the fabric water contact angle (WCA) changed little. Physical stability tests showed that high temperature and ultraviolet radiation had little effect on its superhydrophobicity. In the chemical stability experiment, the fabric was immersed in various organic solvents, salt solutions, and different pH value aqueous solutions for 24 hours, and the superhydrophobicity was generally well maintained, with a significant decrease in WCA only in a strongly alkaline environment. The Si-O-C bonds formed between the methoxysilyl groups in the modifier molecule and the hydroxyl groups on the fabric surface give it excellent stability and durability.

Figure 2 F-D 4-Fabric Water contact angle (WCA) when tested under the following conditions: (a) Number of tape peelings ; (b) Ultrasonic time ; (c) Temperature ; (d) UV irradiation time, (e) Organic solvent immersion, (f) Different pH values and 1 mol L -1 immersion in sodium chloride aqueous solution

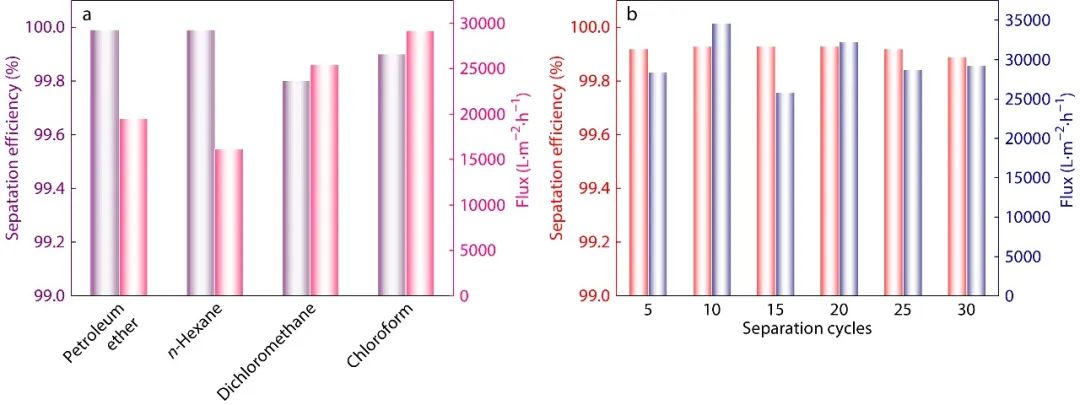

The article systematically studies the F-D4-Fabric oil-water separation performance ( Figure 3) Taking petroleum ether, n-hexane, dichloromethane, and chloroform as representatives, under gravity drive, the fabric exhibits high separation efficiency for both light oil and heavy oil, with a separation efficiency of 99.80%-99.99% Thanks to the excellent chemical stability of the modified fabric, it exhibits good reusability in oil-water separation applications. Taking a mixture of dichloromethane and water as an example, 30 after several cycles, the separation efficiency remains at 99.80% or higher, showing good durability.

Figure 3 (a) Separation efficiency and flux of petroleum ether, n-hexane, dichloromethane and chloroform ; (b) Separation efficiency and flux after different cycles

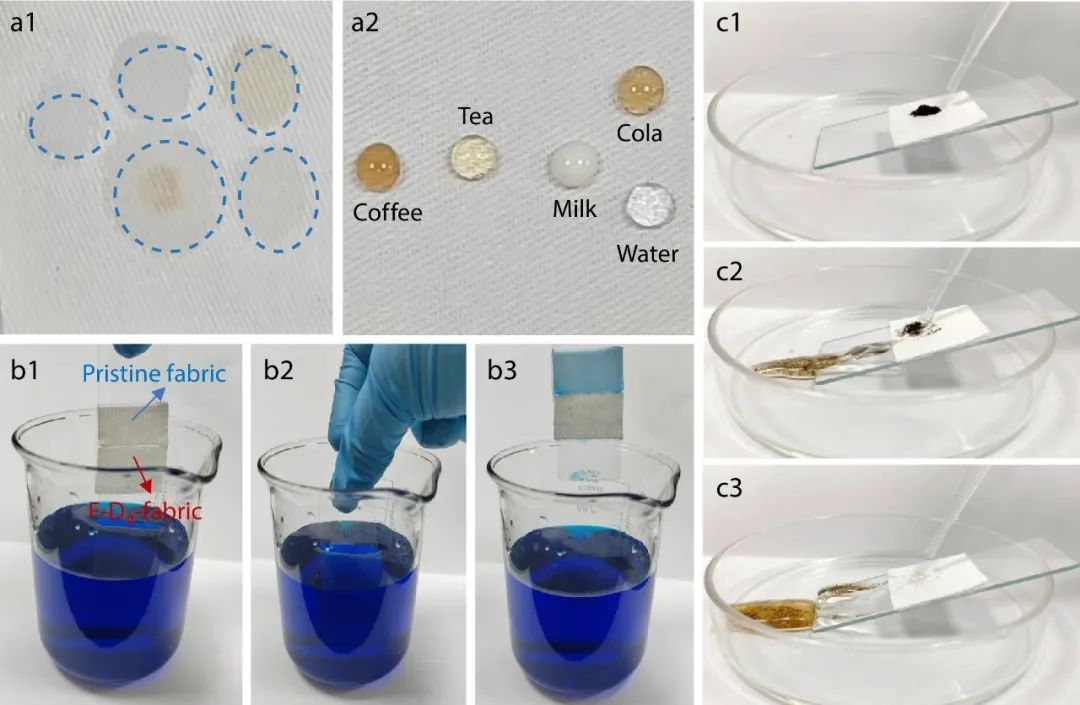

The article demonstrates F-D4-Fabric anti-fouling and self-cleaning properties ( Figure 4) When common liquids such as coffee, tea, and milk are dropped onto the surface of the superhydrophobic cotton fabric, they all form nearly spherical droplets, while the original cotton fabric is quickly wetted. When the original fabric and the modified fabric are immersed in a methylene blue aqueous solution, the original fabric is dyed due to its hydrophilicity and capillary effect, while F-D4-Fabric remains clean and dry, showing effective resistance to water pollution. In the simulated solid pollution experiment, the coated coffee powder quickly mixes and rolls off under the action of water droplets, restoring the fabric surface to cleanliness.

Figure 4 (a) Original fabric and F-D4-Fabric wettability ,' (b)' Original fabric ( on ) and F-D4 -Fabric( under ) immersed in methylene blue aqueous solution ,' (c) F-D4-Fabric' self-cleaning process ( Pollutant: coffee powder )

Liu Mengshu, a master's student, is the first author of this paper, and Professor Liu Hongzhi is the corresponding contact person. This work is supported by the National Key Research and Development Program ( Fund number 2022YFE0197000) Funding.

Original information:

Rational design and fabrication of cyclotetrasiloxane-based hybrid superhydrophobic fabrics for oil/water separation and self-cleaning

Liu, M. S.; Kunthom, R.; Dudziec, B.; ' Liu, H. Z.'

C hinese J. Polym. Sci . 2025, 43, 1022–1031 DOI: 10.1007/ s10118-025-3333-7