Welcome to the official website of Hubei ZhengJiu New Materials Technology Co., Ltd.!

about us

About Us

Hubei ZhengJiu New Materials Technology Co., Ltd.

Hubei ZhengJiu New Materials Technology Co., Ltd. was established in December 2021 as a subsidiary of Hubei Xinshengyuan Bioengineering Co., Ltd. Located at No. 29, Xingye Road, Qingji Industrial Park, Gong'an County, Hubei Province, it covers an area of 235 mu (approximately 156,667 square meters) and plans to build 12 production workshops with a total construction area of approximately 60,000 m².

The company mainly produces more than 50 products in series such as silanes, silicone oils, silicone rubbers, and silicone resins, with an annual production capacity of 50,000 tons. The company has offices and R&D centers in Shanghai and Guangzhou. Adhering to the business philosophy of "building trust with customers, employees, and partners," and upholding the innovative spirit of "passionate dedication, pioneering spirit, integrity and cooperation, and perseverance," ZhengJiu warmly welcomes ambitious individuals to join us and create a new chapter in the organosilicon industry!

Company Established in

Company Land Area

Total Construction Area

products

Product Center

The company mainly produces more than 50 products in series such as silanes, silicone oils, silicone rubbers, and silicone resins, with an annual production capacity of 50,000 tons

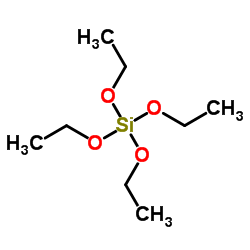

Tetraethyl orthosilicate (TEOS)

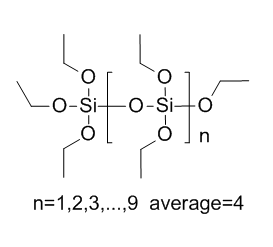

Tetraethyl orthosilicate si40

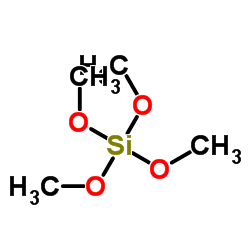

Tetramethyl orthosilicate

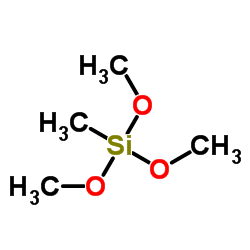

Trimethylmethoxy silane

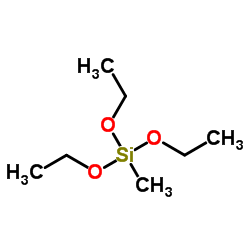

Trimethoxymethyl silane

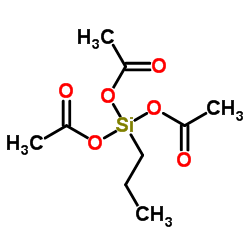

Triacetoxymethylsilane

Triacetoxypropylsilane

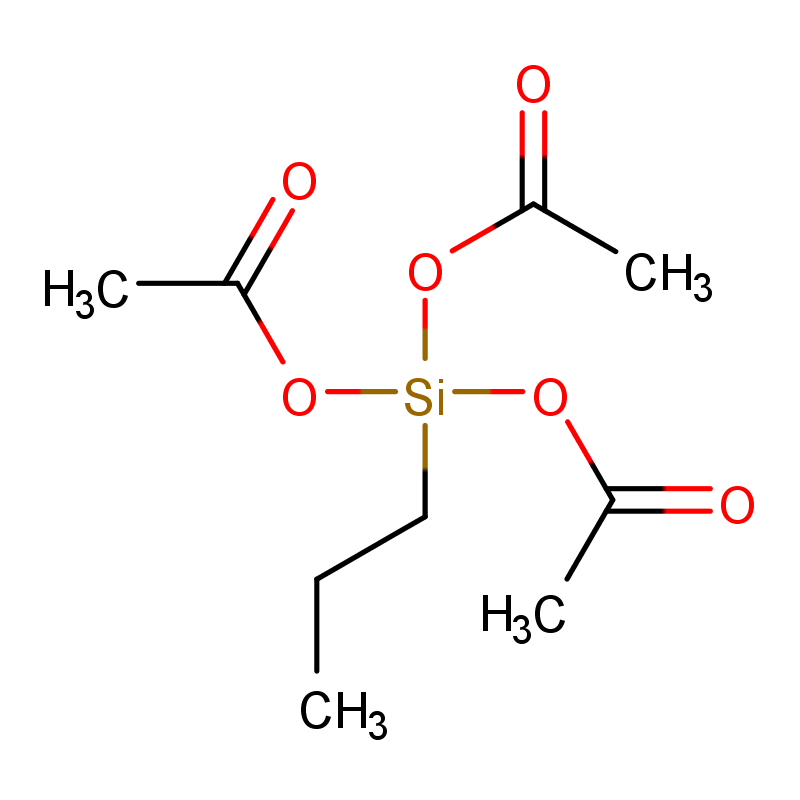

Triacetoxy(methyl)silane

APPLICATION

Product Application Fields

Hubei ZhengJiu's organosilicon products, through the R&D of core raw materials such as silanes and silicone oils, are deeply integrated into high-end industrial chains such as aerogel, aerospace, and medical.

advantage

Why Choose ZhengJiu New Materials?

Hubei ZhengJiu New Materials is committed to providing strong impetus for the long-term growth of enterprises.

Full Industrial Chain Product Matrix

Products cover more than 50 kinds of organosilicon products such as silane, silicone oil, silicone rubber, and silicone resin, forming a complete industrial chain layout.

Scale Production Capacity Support

The company covers an area of 235 mu, plans 12 workshops, has an annual production capacity of 50,000 tons, and has the hard power to quickly respond to market demand.

Dual-Core Drive of Technology Research and Development

The company has established R&D centers in Shanghai and Guangzhou, focusing on cutting-edge fields such as aerogel and electronic packaging, and promoting innovation of high-value-added products.

Deep Penetration into High-End Fields

Products enter high-threshold and high-value-added core tracks such as aerospace thermal protection, medical implant devices, and new energy battery thermal insulation.

Group Resource Synergy

Relying on the industrial resources of Hubei Xinshengyuan Bioengineering Co., Ltd., to achieve efficient integration of capital, technology and market channels.

Innovative Culture and Talent Attraction

Taking "passionate dedication, pioneering and enterprising" as its core values, it builds an open and collaborative team ecosystem, attracting industry elites to create value together.

news

Latest Blog

Follow Hubei ZhengJiu New Materials Technology Co., Ltd. to learn about the company's latest developments

In the industrial sector, there’s a remarkable substance—organic silicon, commonly known as "industrial MSG." Organic silicon materials are a vital component of the nation’s strategic emerging industries in the new materials sector, serving as key high-tech foundational materials that receive significant government support. They are widely used across fields such as construction, healthcare, aerospace, and chemical engineering, making them an essential industrial raw material.

03-17

2026-01-09

After washing your hair with shampoo, your hair feels smooth and tangle-free; the cotton T-shirt you wear is soft and gentle on the skin; and the waterproof windbreaker effortlessly repels rainwater—all these experiences that make life more comfortable owe their magic to the same “invisible hero”: silicone emulsions.